The “MF Technology Awards” is a unique award ceremony that recognises companies who have demonstrated “comprehensive manufacturing capability”. The award recognises machinery and processing manufacturers who have achieved excellence within their industry.

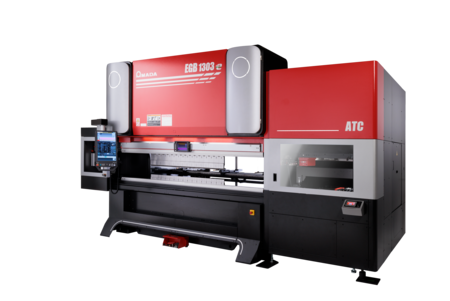

Winner of the New Technology Environment Award was the new AMADA EGB-e Series of bending machines. Recognised for the development of a dedicated servo motor optimised for press brake operation, and for eliminating oil usage by replacing hybrid servo and hydraulic systems with a servo motor system. The EGB-e is packed with the highest technology to aid operators, ensure accuracy and protect the environment. As well as it’s servo drive system the range includes electrical asymmetrical crowning, a new triple backgauge with AR technology, for the first time, voice control and an evolution of AMADA’s bending indicator technology.

The EGB-e series is a direct response by AMADA to the market demand for innovation, high productivity, and importantly, ease of use. This is to mitigate the common problem production companies face in finding and retaining skilled operators.

The skill gap being faced worldwide is one of the main factors for receiving the next award, the NEW Technology Product Award, handed to the FLW-ENSISe Fibre Welding Series with AI-TAS. Welding is an ancient art performed by skilled operators, but the traditional goes hand in hand with poor working conditions and madditional finishing processes, which makes it difficult to attract new staff and ensure productivity. Given the difficulty in securing and training skilled welding operators the AI-TAS teaches, the welder itself, by confirming weld positioning following the correct welding sequence, and subsequently ensures process repeatability.

Additionally, the quality of the welding almost eliminates the need for secondary processes so improving the working environment. Productivity is also improved by nearly 6 times by reducing these subsequent processes. A further 3 Technology awards were presented to the Press categories including the highest award, MF Technology Grand Prize. This grand prize was won in conjunction with Sanyo Seisakusho Co Ltd, together we have been able to combine a digital electric servo press with 3 hydraulic axis, using the cold split-flow forging method and incorporating a hydraulic cylinder, the solution leads to huge cost savings. The cold split-flow forging method reduces the processing load to 2,000kN from 3,000kN, which greatly extends the die life and associated costs.

“We are extremely honoured to have established a highly challenging process method together with Sanyo Manufacturing and received this prestigious MF Technology Award” AMADA Executive Office Mr Yamauchi.