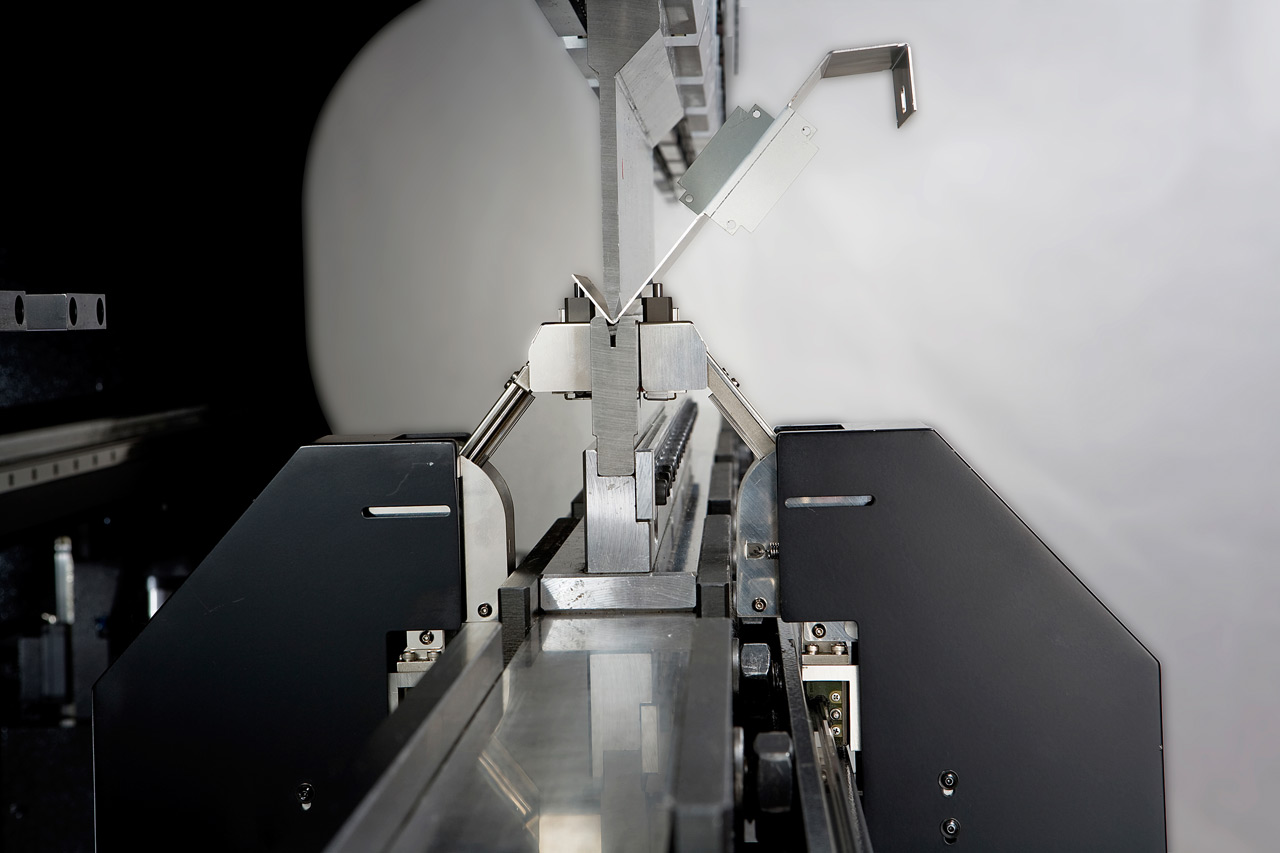

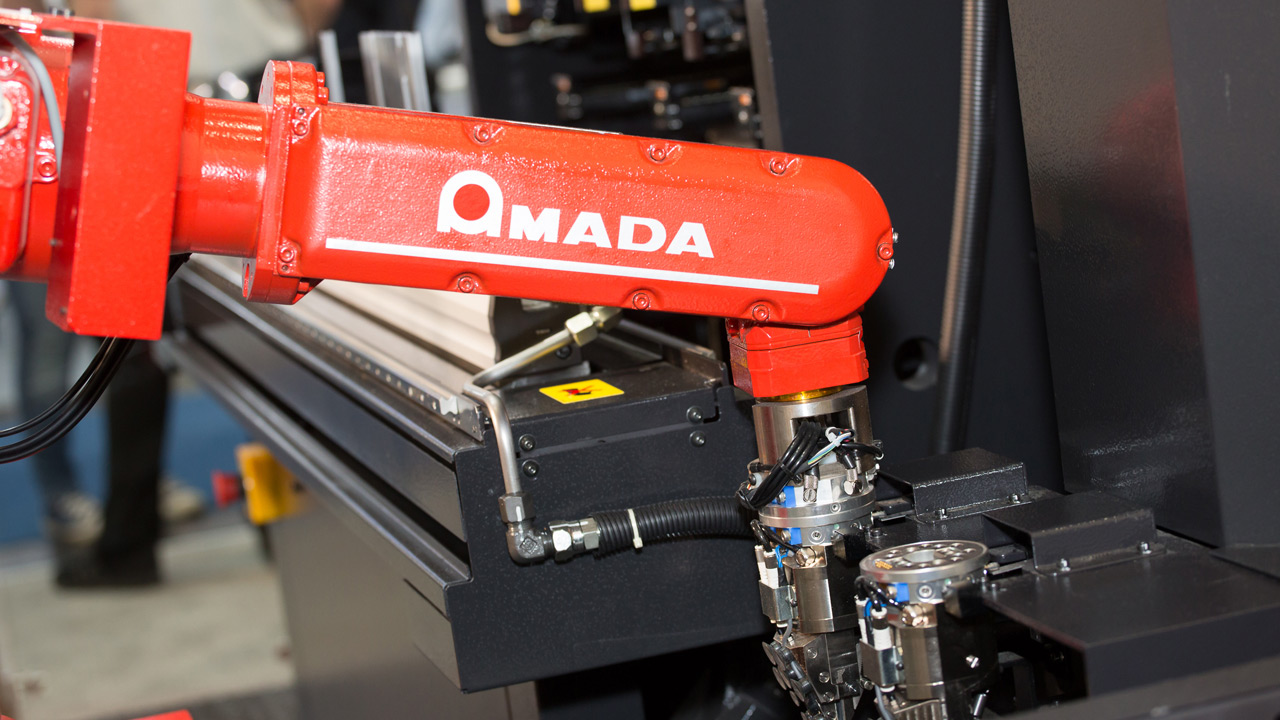

The EG-6013AR combines a fully electric press brake with Dual Servo Power drive (DSP) for high precision and high speed, especially when processing small sized parts. The press brake is combined with a high flexible robot designed for fast, precise bending. Small-sized parts, which are sometimes hard to manually process, can be manufactured automatically, thanks to innovative combined grippers (suction and mechanical grippers). The Automatic Tool Changer and gripper changer ensure fast and accurate set up and a 24/7 production.

MAXIMUM PRECISION AND REPEATABILITY:

The EG-6013AR features a number of devices and characteristics for high precision and repeatability. The AMADA-patented gauging function ensures fast positioning of the part on the back gauges, allowing absolute accuracy over the bend length. The Bi-S device is used to measure and correct the angle in real time, for a precise and accurate result.

AUTOMATIC SETUP:

The cell can carry out a quick and fully automated set up due to tool changer and gripper changer functions. This means different parts can be scheduled, without operator intervention, guaranteeing a very high level of productivity for any kind of batch size.

QUICK AND ACCURATE:

All EG-6013AR components have been designed and developed for maximum speed and precision. The EG-6013 electric press brake, with its exclusive DSP system, dedicated AMADA robot, cell devices, compact layout and dedicated software, offers an integrated solution and unrivalled productivity for any kind of batch size.

| EG-6013AR | |

|---|---|

| Press capacity (kN) | 600 |

| Drive | Servo-Electric press brake |

| Press beam length (mm) | 1275 |

| Distance between frames (mm) | 1010 |

| Stroke (mm) | 150 |

| Open height (mm) | 635 |

| Bending speed (mm/sec) | 25 |

| Approach speed (mm/sec) | 220 |

| Return speed (mm/sec) | 220 |

| Controller | AMNC3i |

| Angle sensor | - |

Robot: | |

| Robot payload incl. gripper (kg) | 10 |

| Manufacturer | YASKAWA |

Gripper: | |

| Gripper types: | Combination type |

ATC (Automated Tool Changer): | |

| Tool stockers | 10 |

| Tool layout length | 15 - 100 |

Loading: | |

| Number of loading positions | 4 |

| Vertical loading | Yes |

| Stack height max. (mm) | 300 |

Unloading: | |

| Number of unloading positions | Up to 4 (depending on configuration) |

| Stack height max. (mm) | 300 |

Part: | |

| Part size length (mm) | 400 x 400 - 550 x 300 |

| Part size width (mm) | 40 x 80 |

| Part thickness max. (mm) | 0.5 - 4.5 |

Technical data can vary depending on configuration / options

Please contact us for more details and options or download our brochure

For your safe use.

Be sure to read the user manual carefully before use.

When using this product, appropriate personal protection equipment must be used.