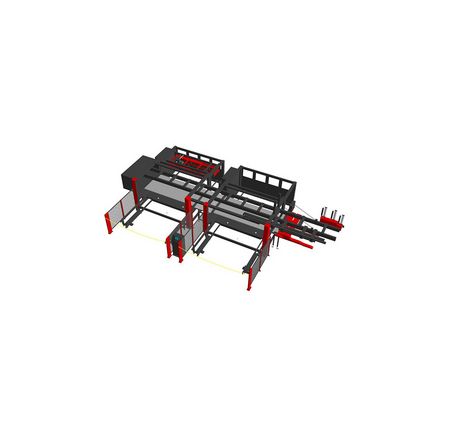

This automation solution has been developed to unlock the maximum productivity of your blanking cell. The “open front” concept allows for rapid one off production, whilst the rear manipulator with integrated Take Out (TK) unit allows for high volume manufacture. The compact, accessible, space saving design ensures productivity and flexibility gains. The combined Rear Manipulator with integrated Take Out (TK) Unit module facilitates safe and reliable automatic loading of raw material and high speed, high precision removing and stacking of processed parts.