Welding is not just a technical process; it is the beating heart of numerous industries, from industrial manufacturing to the medical sector, including electric mobility and precision engineering. Amada, a leader in technological innovation, is transforming this world with cutting-edge solutions that combine efficiency, sustainability, and exceptional quality.

LASER TECHNOLOGY FOR FLAWLESS WELDS

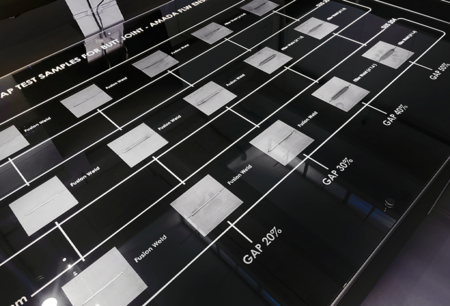

At the core of this transformation lies fiber technology, which prevents deformations and ensures precision even under the most complex conditions. The innovative “Variable Beam Control” laser welding technology allows control of the laser beam’s shape, ensuring superior-quality welds. Additionally, the Beam Weaving system manages beam oscillation, enabling the handling of wider grooves and guaranteeing strength and quality in every application.

Complementing these features are advanced solutions such as the TAS (Teaching Assist System), which automatically recognizes the weld line based on the positioning of the piece, thereby reducing downtime.

Furthermore, with the Filler Push Pull function, filler material can be added to ensure high-quality welding on wide grooves, maintaining excellent final results.

Amada's machines go beyond technical performance: they are compact, with a footprint reduced by up to 65% compared to traditional standards, and highly energy-efficient. This optimizes space, increases productivity, and improves both operator efficiency and the final result.

CUSTOMIZED SOLUTIONS FOR EVERY SECTOR

Amada’s strength lies in its ability to adapt to the needs of diverse industries through advanced technologies and specialized expertise. In the semiconductor field, the company offers solutions that minimize surface deformation; in the medical sector, it produces hermetic and highly reliable instruments, while in the HoReCa world, it ensures processes that reduce the need for finishing, maintaining high-quality standards.

This innovative approach is centered at the Welding Technical Center in Pontenure (PC), a strategic hub where Amada combines technology, automation, and know-how to support customers in every production phase. Here, the Group's divisions work synergistically to offer integrated solutions ranging from cutting and bending to robotic welding, addressing the specific needs of each sector and projecting businesses toward a more innovative future.

INNOVATING TO BUILD THE FUTURE OF WELDING

Amada’s advanced solutions, such as the technologies developed at the Welding Technical Center (WTC), represent our concrete response to the needs of an ever-evolving market. By integrating artificial intelligence and advanced control systems, we enhance production process quality, contributing to a more sustainable and efficient future.

The WTC is not just a technological innovation center; it is a place of collaboration and dialogue. Here, we welcome our customers to discuss their challenges and analyze customized solutions together. Every project is born from direct interaction and a thorough understanding of specific needs, enabling the development of tailored technologies that exceed expectations and tackle the challenges of tomorrow.

Our mission is clear: to build a sustainable, secure, and efficient future together. By combining innovation and vision, we aim not only to improve technology but also to elevate the quality of work and life for those who use our solutions.

Discover how we can transform your workflow [link]