Company holidays

Amada GmbH is closed for company holidays between Christmas and New Year.

More

Amada GmbH is closed for company holidays between Christmas and New Year.

More

ASR3015 PR combines fully automatic loading and unloading as well as parts sorting in a single, particularly compact system. In combination with an EML-AJ, the productivity of the entire line can be increased by 20 to 35%.

More

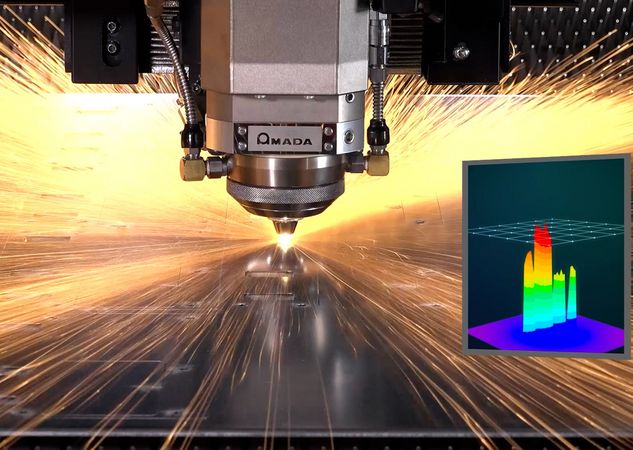

By means of the LBC technology, the VENTIS-3015AJe can cut holes up to 2.5 mm Ø without axis movement. This guarantees almost 100% roundness of the holes and a very high sheet flatness. In this example, 29,000 holes are cut in 3 mm stainless steel (1.4301) with a hole diameter of 1 mm each in about 78 minutes. See for yourself…

More

![ARFT Ball-Chamferingtool - [Tool In Focus]](https://cdn.amada.eu/fileadmin/_processed_/6/0/csm_ARFT_BallChamferTool_EN.00_00_01_01.Standbild002_a53fd8f122.jpg)

Improve the quality of your punched parts with the AMADA ARFT ball deburring tool. With this tool, back punched edges can be deburred quickly, safely and to a high quality in a single operation. The tool, which can be used automatically or manually, is fully compatible with all AMADA CNC turret punching machines and CNC punching laser cutting machines. Cutting and punching sheet metal always requires sharp back cut edges. These are usually deburred to minimize the risk of injury as well as damage to adjacent attachments.

More

Currently our in-house exhibition "It's your SOLUTION" is running in our Solution Center in Haan (05. - 09.12.2022). We are looking forward to many interested visitors.

More

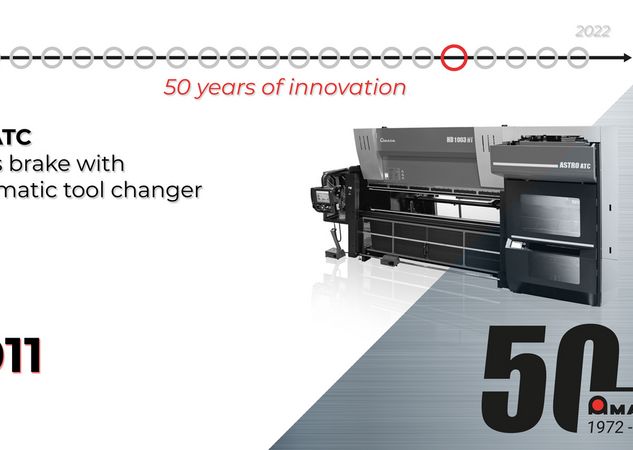

In 2011, the HD-1003 ATC press brake appeared. This standalone machine was equipped with the ATC automatic tool changer for the first time. Set-up time has always been a significant factor in ever-shrinking quantities. The ATC (AutoToolChanger) uses four manipulators to independently transport the tools required for the current program, with a large tool selection available for direct access. The manipulators position the tools extremely precisely on the press beam. In combination with the ATC, the hydraulic die clamping system ensures that the dies are picked up safely.

More

AMADA presents the new HRB-5020, a new, compact and powerful system with 500 kN press force. Highlights of the new press brake include the newly designed lower press beam for constant bending angles over the entire length of 2,150 mm, an increased opening width to 520 mm and a stroke of 250 mm. Lite mode has been added to the AMNC3i control, making it even easier to program.

More

Our latest fiber laser cutting machine VENTIS-3015AJe has arrived in Haan! First presentation at EuroBLECH 2022 in Hannover, in December LIVE at our SOLUTION in Haan! Our BESTSELLER 2021 is now available with increased power: - 6 kW for more excellent cutting quality even with thicker materials - Increased productivity due to higher cutting speed We cordially invite you to the presentation of the VENTIS-3015AJe & our 50th company anniversary . Register today and look forward to other highlights in addition to the VENTIS-3015AJe: https://haan.amada.de.

More

Kochertaler-Metall-Gestaltung GmbH has upgraded its production with two AMADA machines: Press brake HFE-2204M2 and shear GX II-1230.

More

In 2011, AMADA presented the FLW series, a robotic welding cell with a fiber laser. In addition to steel, stainless steel and aluminum, fiber laser technology enables the largely problem-free processing of challenging materials such as copper, brass and titanium.

More![Long Board Punch - [Tool In Focus]](https://cdn.amada.eu/fileadmin/_processed_/c/0/csm_LongBoardPunch_EN.00_00_00_28.Standbild005_d7ffb688a8.jpg)

The long board punch enables the folding of closed profiles that cannot be produced with conventional goad punches. The tool is ideal for the production of closed profiles or high U-profiles.

More

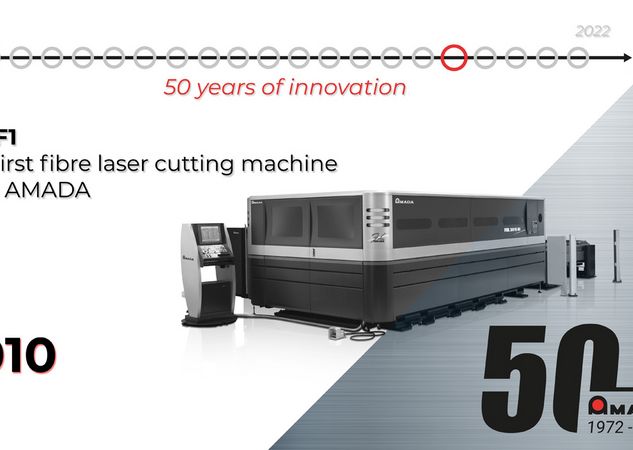

The future of laser cutting began in the fall of 2010. At EuroBLECH 2010 in Hanover, AMADA presented a new laser technology. For the first time, the FOL NT series was equipped with a fiber laser. AMADA won the MM Award 2010 in the cutting category with this new machine.

More

Delivery of an ENSIS-4020AJ fiber laser cutting system at GEMTEC AG.

More

The Solution Center in Haan was opened in 2009. The overall concept of the buildings is part of the objective to support our customers consistently and in the best possible way in being innovative, competitive and economical in the future. In the Solution Center, the focus is not just on exhibiting the technologies, but on a cross-solution offering comprising analysis, consulting and training. In this way, the user is comprehensively informed and trained about the latest developments in the field of metal production.

More

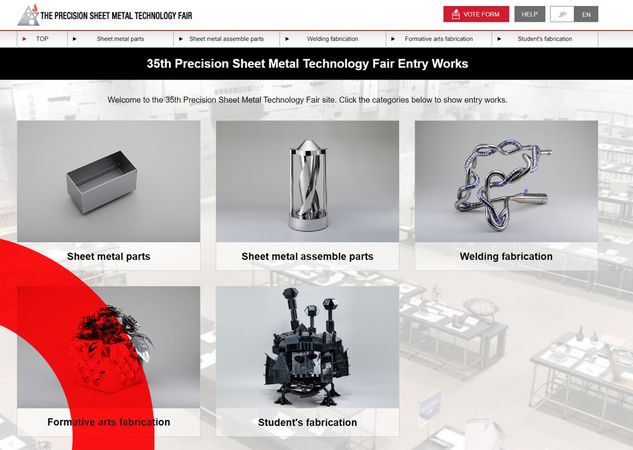

We would like to invite you to participate in the online voting for the 35th AMADA Precision Sheet Metal Technology Fair. Your participation and unique manufacturing expertise will ensure that the best candidates are awarded. If you click here, you can view all entries to this international competition.

More

![ARFT Offset Tool - [Tool In Focus]](https://cdn.amada.eu/fileadmin/_processed_/c/4/csm_Screenshot_2022_546_7263db08a8.jpg)

Welcome to our new series: Tool In Focus , where we will be demonstrating our vast range of tools to improve your productivity within the workplace. Are you looking to enhance your component quality and production flexibility? The AMADA ARFT offset tool, could be the solution for you.

More

Flexibility, handling, economy and reliability were the decisive requirements which the F1 series from AMADA reliably met in 2007. With significantly improved performance parameters and various technological innovations, these laser cutting machines convinced both economically and ecologically. The LC-F1 NT laser machine won the MM Award at EuroBLECH 2008 in the “Flexible Sheet Metal Processing” category.

More

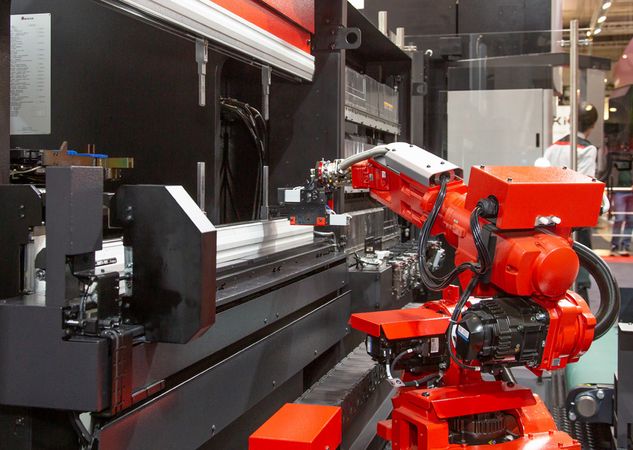

The new AMADA EGB-6013ARce is an electric, fully automatic bending cell. It offers 35% more tool capacity and reduces cycle times by up to 36 percent. Read more: https://www.amadamarker.com/2022/10/24/amada-egb-6013arce-elektrische-komplettzelle/

More

AMADA’s EML Z sheet metal processing center not only offered punching and laser technology in one machine: The combination of semi-flying optics with the patented servo electric punch drive and a punching force of 300 kN resulted in an entirely new level of flexibility and energy efficiency.

More

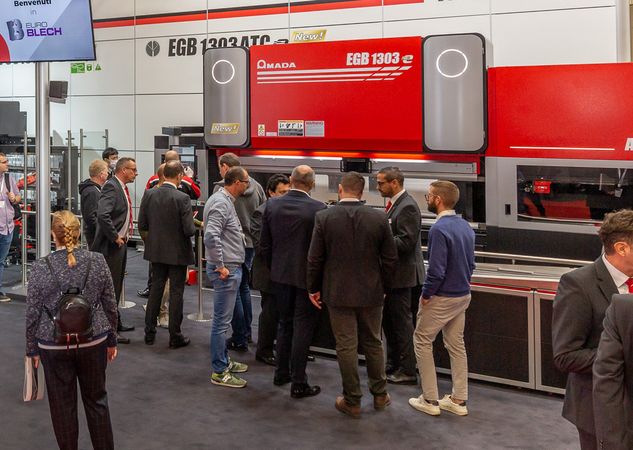

With the AMADA EGB-1303ATCe, AMADA is presenting for the first time at EuroBLECH 2022 an all-electric press brake with 130 t pressing force and 3 m bending length. The system no longer requires any hydraulic oil, is energy-efficient in operation and simple to set up and maintain.

More

Discover at EuroBLECH 2022 our press brake type HRB, which brings even higher accuracy with the new automatic crowning device and improved flexibility to the mid-range range.

More

The winners of this year’s EuroBLECH Awards have been announced! With over 9,000 votes in 5 categories, these innovations convinced our online users and were awarded the EuroBLECH Award 2022

More

The EuroBLECH 2022 starts next week. Don’t miss the premiere of AMADA’s brand new innovative technology. We look forward to seeing you at our booth: D06/F06 in Hall 12.

More

Vote now for the REGIUS-3015AJe with the new AMNC4ie laser control. This control recognizes the operator and automatically switches the display languages as well as the user interface. This significantly improves productivity and avoids errors. In addition, the mobile HMI enables continuous status monitoring from remote locations and allows multiple machines to be operated. This year marks the 10th time that the “EuroBLECH Award” has been presented. Prizes are awarded for the most innovative products, solutions and digitization concepts at the international technology trade fair for sheet metal working.

More

AMADA GmbH News EuroBLECH Award 2022 – EGB-1303ATCe 14. October 2022 Kathrin Soroka-Morzinietz Bending Electric press brake EGB-1303ATCe Share this content Vote now for the new developed electric press brake EGB-1303ATCe with the innovative drive technology. The individual 4-axis control realizes high-precision bending for any positions and angles. The new backgauge eliminates the limitation of parts shapes. The newly developed AMNC4ie/Tablet HMI automatically moves to work positions and shows process guidance to minimize defect parts. The automatic tool change system reduces workloads. The next-generation human- and environment-friendly machine. The “Euroblech Award” is being presented for the 10th time this year. Awards are given for the most innovative products, solutions and digitalization concepts at the international technology trade fair for sheet metal working.

More

Delivery of a ENSIS-3015 at Laska Metaal B.V. Amada wishes you succes with the new Ensis fiberlaser!

More

ZWILLING J.A. Henckels AG has expanded its machine park with another ALPHA-2415 laser machine. Thanks also to Eugen Scalabrin GmbH & Co for the machine installation. We wish you much success with the plant!

More

Delivery of a HFE-1704M2 press brake at RRH – Blechzentrum GmbH in Düren – Konzendorf. Thanks also to Josef Pohl GmbH + Co. KG for the machine loading. We wish much success with the plant!

More

Delivery of the 1st ENSIS-3015RI (9kW) raw axis laser machine in Europe at MetallForum Metallbau GmbH in Giesen.

More

Anlieferung einer HFE3i-1003 Abkantpresse bei der HW Metall Design GmbH in Saalstaft. Wir wünschen viel Erfolg mit der Anlage!

More

Delivery of an LC-2415 ALPHA V at PSW-Umformtechnik GmbH in Elze.

More

Delivery of a HFE3i-1003L pressbrake at Promed Computertechnik GmbH in Dresden. We wish you much success with the plant!

More

With the Bendamatic bending robot BM-100, Amada ushered in a new era in forming technology. A system was developed that simply does everything automatically – from the material supply to the complete bending technology to the stacking of the finished parts. The production cell – consisting of an FBD press brake, BM-100 bending robot, loading and unloading unit – opened up completely new perspectives in the small and medium-sized series sector. The simultaneous movement of 5 axes allowed the sheet metal blanks to be handled as if by human hands.

More

Metal Technology GmbH has expanded its machinery with a punch-laser combination EML-2515AJ. Thanks also to TBM Maschinenhandel GmbH and Sälzer Autokrane + Transporte GmbH for the machine installation. We wish you much success with the plant!

More

Promecam started manufacturing and selling press brakes in France in 1955. As early as 1965, AMADA took over the distribution of Promecam press brakes in Asia. In 1986, the Promecam company was then completely taken over by the AMADA Group - the start of the company's own production of AMADA press brakes in and for Europe.

More

Delivery of an HFE3i-2203 pressbrake at Willme Laser- und Stanztechnik GmbH & Co. KG. This press brake replaces an HFE-2204 (year of manufacture 2002).

More

The world’s first industrially used series laser LC-644 represents a significant milestone in the history of AMADA.

More

From 05.07. – 07.07.2022 AMADA GmbH welcomed interested companies and customers to the in-house exhibition at the Technical Center Landshut. In addition to the latest technologies such as the HRB edging series or the fully automated REGIUS laser cutting system with linear drives, the personal contact and exchange of experiences was not neglected. The highlight was certainly the Bavarian evening in our 1st lobby with suckling pig and draft beer, where new contacts could be made and existing relationships strengthened in a cozy atmosphere. We would like to thank the numerous visitors for a successful 3 days of SOLUTION!

More

The KW Group includes the suspension manufacturer KW automotive with its brands KW suspensions, ST suspensions, ap sport suspensions and the SimRacing brands TrackTime and Ascher Racing.

More

In the next six months we will take you on our journey through time “50 years of innovation – 50 years of AMADA GmbH in Germany”.

More

Investment in the future – The company Dinzl Ordnungstechnik GmbH expands its machinery with a fully automatic bending cell HG 1003 ARs from AMADA.

More

The VQC is an optical measuring machine for use in production. The workpieces are placed on an inclined glass plate and optically recorded by means of a CCD camera. Subsequently, the camera image is superimposed on the CAD file of the scanned workpiece on the computer. Our customer BlechCon GmbH & Co. KG takes delivery of a VQC-1220

More

This week: i-Process Monitoring-System. AMADA’s i-Process Monitoring system constantly monitors all cutting and piercing operations and takes action when necessary to keep the machine producing parts. The protective glass of the cutting lens is monitored by the i-Optics sensor, which alerts the operator when the protective glass needs to be replaced to avoid potential interruptions.

More

AMADA BRINGS AUTOMATIC TOOL CHANGING TO THE MID-RANGE PRESS BRAKE MARKET

More

This week: i-Camera Assisted System (i-CAS) The i-Camera Assisted System (i-CAS) from AMADA enables perfect rest sheet processing.

More

Experience our latest technologies LIVE and visit us at our in-house exhibition "SOLUTION" from 05 - 07.07.2022 in Landshut!

More

This week: Deep-etch function Deep-etch engraving enables part traceability throughout the manufacturing process. Even after painting, coating or electroplating.

More

We congratulate Lang Gerätetechnik GmbH for the new fiber laser cutting system with twin towers for loading and unloading and wish them every success with the new system. Watch the video of the delivery of the 100th VENTIS-3015AJ in Europe & the ASF-EU Twin Tower.

More

ENSIS-6225AJ – Fiber laser cutting machine for processing 6.2 x 2.5 m sheets 5 weeks – 5 outstanding features This week: Automatic cutting area cooling (WACS II) AMADA’s new WACS II cutting area cooling system is used for processing thick mild steel and enables even more efficient cooling thanks to different setting variants. Material costs play an extremely important role. WACS II enables significantly better material utilization by allowing closer nesting of parts. Even with very thin wall thicknesses, e.g. 3 mm in 25 mm mild steel, a high cutting quality is guaranteed.

More

In the AMADA online inquiry portal, the ALPHA Guide ID punch guide units are now also available in the station sizes: 'C' Station (2" / 50.8 mm), 'D' Station (3½" / 88.9 mm), 'E' Station (4½" / 114.3 mm). Maximum material utilization, Quick adjustment of the punch length by means of a push button, One touch system for changing the 3 different types of stripper plates

More

Register now for the webinar on 02.06.2022

More

From 09-13 May 2022 our in-house exhibition "SOLUTION" took place in Reutlingen. Besides our guillotine shear GX II-1230 and press brake HFE3i-5012, we presented our bestseller 2021 - the fiber laser cutting machine VENTIS-3015AJ.

More

For 2 more days, we will present our BESTSELLER 2021, the fibre laser cutting machine VENTIS-3015AJ with innovative LBC technology, as well as our all-round press brake HFE3i-5012 at our booth 0633 in hall 20. More information and free tickets are available here: intertool.amada.de

More

Two punch-laser combination machines were set in motion at our customer Plasmacut Metallverarbeitung GmbH in one day: the old FLCP2515AJ20 was collected and a new EML-2515AJ with fibre laser was delivered. We wish you much success with the new machine!

More

Half time – day 4 of the construction and in 4 days the Intertool 2022 will start. After the machines have been installed this week, the construction of the actual booth starts now. Visit AMADA at the Intertool in Wels, from May 10-13, 2022 / Hall 20, Booth 0633. You can find all information here: https://intertool.amada.de

More

Delivery of an EMK-3612MII punching machine at Dillinger Edelstahlverarbeitung GmbH & Co. KG. The plant was automated with an L III 300 loading system and a PR III UL 300 P unloading system. Thanks to Steil Kranarbeiten GmbH & Co. KG for the machine installation. We wish you much success with the plant!

More

Here we go! Day 1 of the build-up. The first machines were unloaded today in Hall 20.

More

For today’s Dutch Koningsdag 2022, we immortalized the royal couple Máxima und Willem-Alexander using the AMADA ArtPunch software and a total of 28,412 punched holes in a metal sheet.

More

Time-lapse of the assembly of a CSII storage system with an LCG-3015 AJ (9kW) fiber laser and an FO-4020 NT (4kW) CO₂ laser machine at Gebr. Bruns GmbH

More

Delivery of a HG-2204ATC press brake at Wieneke Anlagenbau und Verfahrenstechnik GmbH in Bad Driburg

More

he AMADA online inquiry portal now also offers additives for AMADA punching tools. The AM557 is a cutting oil for the use of threading tools & tapping tools. The oil is available in 4 liter (order number: 0394012E) and 20 liter (order number: 0394013E).

More

AMADA GmbH wishes you a happy Easter and relaxing bank holidays

More

Visit our in-house exhibition from 9-13 May 2022! We looking forward to seeing you!

More

Experience the latest technologies from 10.-13. May 2022.

More

AMADA announces the 100th European order for its VENTIS Fiber Laser featuring the revolutionary Locus Beam Control Technology.

More

Delivery of an HFE3i-2204L pressbrake, the third of three new machines at gunkel systeme GmbH & Co. KG in Kassel. Congratulation on the expanded machine park and wish it every success!

More

The AMADA online inquiry portal includes additive for laser machines. The EM320-AM (OrderNo: 71577494) is for WACS cutting (Water Assisted Cutting System). The cutting area of the sheet is cooled with a water spray, which significantly improves the quality of the cut surface and allows smaller material webs to be used, resulting in significantly more efficient material utilization.

More

Many new and proven AMADA technologies are utilised to provide the highest levels of cutting performance to keep customers at the competitive edge.

More

Find out more about your career opportunities at AMADA! http://career.amada.de

More

Delivery of another HG-1003ATC press brake at WOLF GmbH in Mainburg. Thanks also to KLEMA GmbH for the machine installation. We wish much success with the machine!

More

In the night to Sunday the summer time (CEST) has begun and with it the cherry blossom at the Amada Allee in Haan. Sunny greetings

More

A beautiful first week of spring and an equally beautiful first in-house exhibition this year is behind us . Our visitors experienced our latest #technologies up close, had interesting conversations in a personal atmosphere and were able to gain new impulses for their own production. We would like to thank all visitors and contributors for this great trade show!

More

In view of the ongoing and expanding armed conflict in Ukraine, the plight and suffering of Ukrainians both in the country and on the run, and thus their need for humanitarian aid, is becoming more urgent and greater

More

In perfect spring weather master students from the Münster Chamber of Crafts visited us at our Solution Center in Haan. They were given a close-up demonstration of our exhibited technologies at various stations in small groups. And those who wanted to were also allowed to try out the machine themselves . We would like to thank them very much for their visit to our company!

More

The 34th “Precision Sheet Metal Technology Fair” has taken place in Japan. The competition has been organized by AMADA School Japan since 1989. The aim is to showcase the capabilities and know-how of the sheet metal processing industry.

More

Every year AMADA CO., LTD. designs a pattern piece with the zodiac sign of the year! This year it is a design with a Tiger, the zodiac sign of 2022 on the back of Fuji

More