AMADA’s FLW-ENSISe series represents the evolution of laser welding, combining efficiency, automation, and precision. Thanks to the integration of a rail-mounted robot, rotating tables, and ENSIS laser technology, these solutions offer maximum flexibility to handle parts of various sizes and complexities. The ability to modify the laser beam shape allows welding to be adapted to specific production needs, ensuring flawless results even on complex materials and geometries.

FLW-ENSISe M3: FLEXIBILITY AND PRECISION

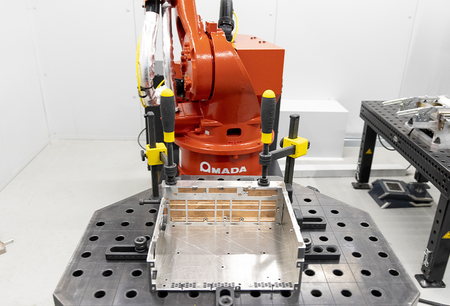

The FLW-ENSISe M3 model is designed to ensure high operational versatility, featuring a robot with a 50 kg payload mounted on a 3-meter rail. This system enables the robot to move along the linear axis, expanding the working area and allowing the welding of large parts without complex repositioning.

A distinctive feature is the integrated tilting table, which can rotate 360° and tilt up to 90°, improving accessibility to hard-to-reach areas. This reduces the time required for part handling and ensures precise welding, even on curved or angled surfaces.

FLW-ENSISe M3 is available in two configurations:

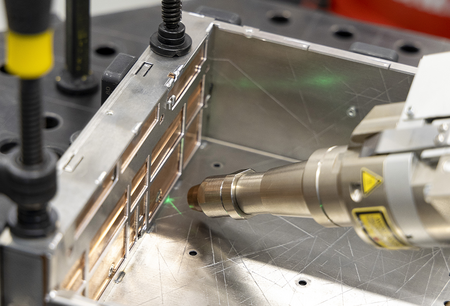

Thanks to ENSIS technology, the laser beam can be adapted to the specific process, shifting from a cone-shaped beam—ideal for maximum penetration—to a ring-shaped beam, perfect for joining parts with small gaps without requiring filler material.

FLW-ENSISe M5: CONTINUOUS PRODUCTIVITY

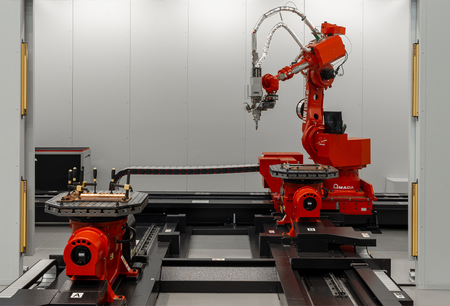

For those requiring maximum productivity, the FLW-ENSISe M5 model introduces additional advantages. The robot is mounted on a 4-meter rail, increasing the working area and enabling the handling of even larger and more complex components.

One of M5’s key benefits is the presence of two independent rotating tables, allowing welding on one piece while the operator prepares the next. This system drastically reduces downtime, enhancing production efficiency.

Beam management is also optimized: in addition to beam shape variation, the M5 model includes an automatic focal adjustment system and integrates AI-TAS artificial intelligence. This technology enables the coaxial camera to recognize the part’s position and automatically correct any misalignment, ensuring consistently precise welds without manual intervention.

FLW-ENSISe M5 is ideal for industries requiring high productivity, precision, and continuous operation, such as metal fabrication, the medical device industry, and the HoReCa sector.

FLW-ENSISe: INNOVATION AND CUSTOMIZED PERFORMANCE

AMADA’s FLW-ENSISe series stands out as one of the most advanced solutions in laser welding, offering versatility, automation, and top-tier production quality. With the M3 and M5 models, companies can choose the most suitable configuration for their needs, optimizing production times and the final quality of their products.

Discover more about AMADA solutions and the FLW-ENSISe range.