AS LUL - STRI

More

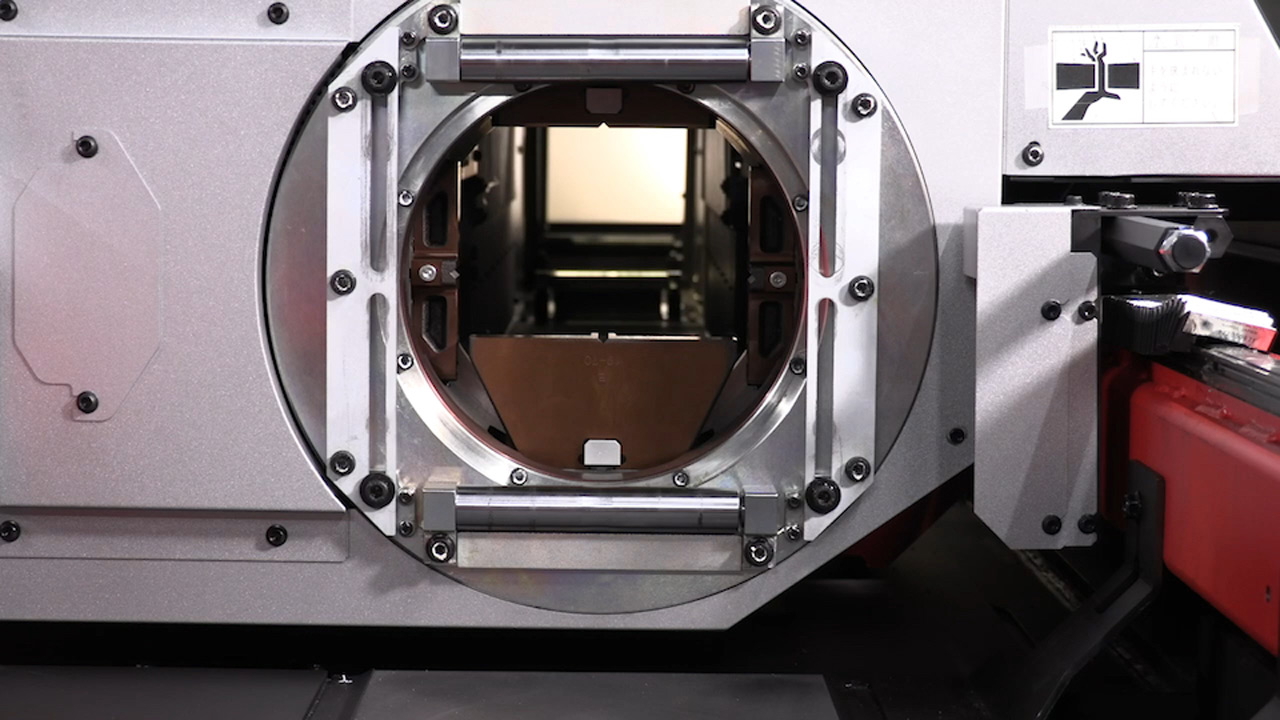

The fibre laser tube cutting machine ENSIS-RI can process round, square and rectangular tubes as well as channel and angle profiles. AMADA has combined two unique technologies to give you the ultimate flexibility when it comes to sheet metal processing. ENSIS technology for laser beam control and the proven Rotary Index system for tube cutting are combined in a machine that can deliver on an extensive range of production requirements. All with a single machine, at lower costs and maximising your productivity.

FLEXIBILITY:

The ENSIS-RI can process round, square and rectangular tubes as well as channel and angle profiles. Thanks to a single cutting lens and automatic nozzle changer, all materials, thicknesses and profiles can be processed with minimal setup.

STREAMLINED SETUP:

The next flat sheet or tube profile to be processed can be setup while the machine is cutting. In addition, to reduce setup time, ENSIS-RI features “One Touch” quick change jaws which are used to provide accurate clamping of different size tubes.

QUICK TRANSITION FROM SHEET METAL TO TUBES:

With the ENSIS-RI, the transition from processing sheet metal to tubes is quick and simple, with setup taking as little as 5 minutes.

| ENSIS-3015RI | ENSIS-3015RI | ENSIS-3015RI | ENSIS-3015RI | |

|---|---|---|---|---|

| Laser power (W) | 3000 | 6000 | 9000 | 12000 |

| Machine type | Fibre laser cutting machine | Fibre laser cutting machine | Fibre laser cutting machine | Fibre laser cutting machine |

| Working range X x Y (mm) | 3070 x 1550 | 3070 x 1550 | 3070 x 1550 | 3070 x 1550 |

| Working range Z-axis (mm) | 200 | 200 | 200 | 200 |

| Repeatable positioning accuracy (mm) | ± 0.01 | ± 0.01 | ± 0.01 | ± 0.01 |

| Table loading weight (kg) | 920 | 920 | 920 | 920 |

| Drive system | Helical rack and pinion | Helical rack and pinion | Helical rack and pinion | Helical rack and pinion |

Rotary Index Specifications: | ||||

| Round tube Ø (mm) | 19 - 220 | 19 - 220 | 19 - 220 | 19 - 220 |

| Square tube (mm) | 19 - 150 | 19 - 150 | 19 - 150 | 19 - 150 |

| Rectangular tube across diagonals (mm) | 220 | 220 | 220 | 220 |

| Channel profile (mm) | 19 - 150 | 19 - 150 | 19 - 150 | 19 - 150 |

| Angle profile (mm) | 19 - 130 | 19 - 130 | 19 - 130 | 19 - 130 |

| Maximum tube weight (kg) | 200 | 200 | 200 | 200 |

| Maximum tube length (mm) | 6000 | 6000 | 6000 | 6000 |

| Tube / profile wall thickness (mm) | 1 - 9 | 1 - 9 | 1 - 9 | 1 - 9 |

| Angle / Channel wall thickness (mm) | 1 - 12 | 1 - 12 | 1 - 12 | 1 - 12 |

Material thickness (max.)*: | ||||

| - Mild steel (mm) | 25 | 25 | 25 | 25 |

| - Stainless steel (mm) | 15 | 25 | 25 | 25 |

| - Aluminium (mm) | 12 | 25 | 25 | 25 |

| - Brass (mm) | 8 | 15 | 18 | 18 |

| - Copper (mm) | 6 | 12 | 12 | 12 |

Dimensions: | ||||

| Length (mm)* | 12505 | 12505 | 12505 | 12505 |

| Width (mm) | 2915 | 2915 | 2915 | 2915 |

| Height (mm) | 2532 | 2532 | 2830 | TBC |

| Weight (kg) | 14000 | 14400 | 14500 | TBC |

* Maximum thickness value depends on material quality and environmental conditions

** Machine + shuttle table (LST)

Technical data can vary depending on configuration / options

Please contact us for more details and options or download our brochure

For your safe use.

Be sure to read the user manual carefully before use.

When using this product, appropriate personal protection equipment must be used.

Laser class 1 when operated in accordance to EN 60825-1