Available with 3, 6, 9 and 12kW fibre laser engines developed by AMADA using 3 and 4kW diode modules, the ENSIS-AJ range considerably increases your production capacity. The 6kW, 9kW and 12kW versions utilise AMADA’s Auto Collimation system, for unrivalled laser beam spot control. Combined with AMADA's original Variable Beam Control technology to adjust the laser mode, this system can process different materials and thicknesses with a single cutting lens. The quality and processing speeds for medium to thick materials, as well as very high-speed piercing, make the ENSIS-AJ the perfect machine to increase your profitability.

DOWNLOAD BROCHURE DOWNLOAD BROCHURE ENSIS-6225AJ

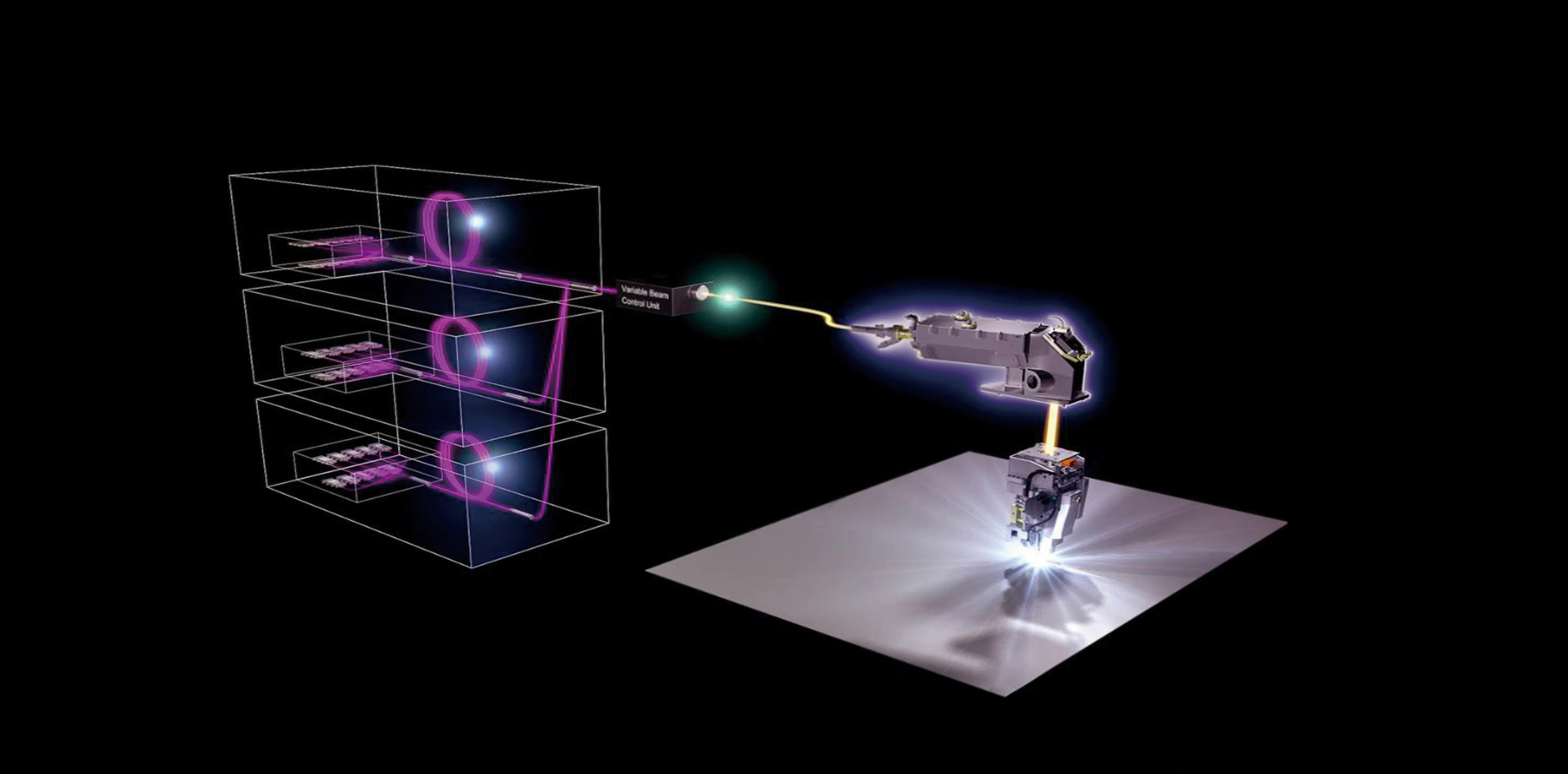

VARIABLE BEAM CONTROL UNIT & AUTO-COLLIMATION SYSTEM:

With ENSIS technology, we can modify the mode of the laser beam based on the material thickness, guaranteeing an outstanding performance whilst using a single lens for all materials and thicknesses. Thanks to the Auto Collimation system (on the 6, 9 and 12kW versions), the full processing power of the laser can be used without compromise.

AMADA FIBRE LASER ENGINE:

AMADA was the first laser machine manufacturer worldwide to develop its own fibre laser engine in-house, specifically designed for cutting. Beam density and cutting quality have been improved and maintenance costs drastically reduced.

SIDE DOOR:

The ENSIS-AJ has been fitted with large front and side opening doors, for more convenient and flexible access to the cutting area.

| ENSIS-3015AJ | ENSIS-3015AJ | ENSIS-3015AJ | ENSIS-3015AJ | |

|---|---|---|---|---|

| Laser power (W) | 3000 | 6000 | 9000 | 12000 |

| Machine type | Fibre laser cutting machine | Fibre laser cutting machine | Fibre laser cutting machine | Fibre laser cutting machine |

| Working range X x Y (mm) | 3070 x 1550 | 3070 x 1550 | 3070 x 1550 | 3070 x 1550 |

| Working range Z-axis (mm) | 100 | 100 | 100 | 100 |

| Repeatable positioning accuracy (mm) | ± 0.01 | ± 0.01 | ± 0.01 | ± 0.01 |

| Table loading weight (kg) | 920 | 920 | 920 | 920 |

| Drive system | AC Servo drives | AC Servo drives | AC Servo drives | AC Servo drives |

Material thickness (max.)*: | ||||

| - Mild steel (mm) | 25 | 25 | 25 | 25 |

| - Stainless steel (mm) | 15 | 25 | 25 | 25 |

| - Aluminium (mm) | 12 | 25 | 25 | 25 |

| - Brass (mm) | 8 | 15 | 18 | 18 |

| - Copper (mm) | 6 | 12 | 12 | 12 |

Dimensions: | ||||

| Length (mm)** | 10136 | 10136 | 10136 | 10136 |

| Width (mm) | 2840 | 2840 | 2840 | 2840 |

| Height (mm) | 2432 | 2432 | 2730 | 2500 |

| Weight (kg) | 9100 | 9500 | 9600 | 9700 |

| ENSIS-4020AJ | ENSIS-4020AJ | ENSIS-4020AJ | ENSIS-4020AJ | |

|---|---|---|---|---|

| Laser power (W) | 3000 | 6000 | 9000 | 12000 |

| Machine type | Fibre laser cutting machine | Fibre laser cutting machine | Fibre laser cutting machine | Fibre laser cutting machine |

| Working range X x Y (mm) | 4070 x 2050 | 4070 x 2050 | 4070 x 2050 | 4070 x 2050 |

| Working range Z-axis (mm) | 100 | 100 | 100 | 100 |

| Repeatable positioning accuracy (mm) | ± 0.01 | ± 0.01 | ± 0.01 | ± 0.01 |

| Table loading weight (kg) | 1570 | 1570 | 1570 | 1570 |

| Drive system | AC Servo drives | AC Servo drives | AC Servo drives | AC Servo drives |

Material thickness (max.)*: | ||||

| - Mild steel (mm) | 25 | 25 | 25 | 25 |

| - Stainless steel (mm) | 15 | 25 | 25 | 25 |

| - Aluminium (mm) | 12 | 25 | 25 | 25 |

| - Brass (mm) | 8 | 15 | 18 | 18 |

| - Copper (mm) | 6 | 12 | 12 | 12 |

Dimensions: | ||||

| Length (mm)** | 12080 | 12080 | 12080 | 12080 |

| Width (mm) | 3360 | 3360 | 3360 | 3360 |

| Height (mm) | 2432 | 2432 | 2730 | 2500 |

| Weight (kg) | 12200 | 12800 | 12900 | 13000 |

| ENSIS-6225AJ | ENSIS-6225AJ | ENSIS-6225AJ | |

|---|---|---|---|

| Laser power (W) | 6000 | 9000 | 12000 |

| Machine type | Fibre laser cutting machine | Fibre laser cutting machine | Fibre laser cutting machine |

| Working range X x Y (mm) | 6200 x 2580 | 6200 x 2580 | 6200 x 2580 |

| Working range Z-axis (mm) | 200 | 200 | 200 |

| Repeatable positioning accuracy (mm) | ± 0.01 | ± 0.01 | ± 0.01 |

| Table loading weight (kg) | 4020 | 4020 | 4020 |

| Drive system | AC Servo drives | AC Servo drives | AC Servo drives |

Material thickness (max.)*: | |||

| - Mild steel (mm) | 25 | 25 | 25 |

| - Stainless steel (mm) | 25 | 25 | 25 |

| - Aluminium (mm) | 25 | 25 | 25 |

| - Brass (mm) | 15 | 18 | 18 |

| - Copper (mm) | 12 | 12 | 12 |

Dimensions: | |||

| Length (mm)** | 17414 | 17414 | 17414 |

| Width (mm) | 4165 | 4165 | 4165 |

| Height (mm) | 2310 | 2310 | 2310 |

| Weight (kg) | 33500 | 33500 | 33500 |

* Maximum thickness value depends on material quality and environmental conditions

** Machine + shuttle table (LSTe)

Technical data can vary depending on configuration / options

Please contact us for more details and options or download our brochure

For your safe use.

Be sure to read the user manual carefully before use.

When using this product, appropriate personal protection equipment must be used.

Laser class 1 when operated in accordance to EN 60825-1