The HG-Rm has been designed to automate the bending process for medium and large size parts, for applications where bending requires long hours and significant operator effort, especially for large or heavy parts, when two operators are required. The solution is based on the top-end HG-1303 range, designed to meet production requirements through a hybrid technology and extremely robust structure. The machine is integrated with a 7-axis robot and a number of smart devices designed to facilitate the bending of complex parts and large panels.

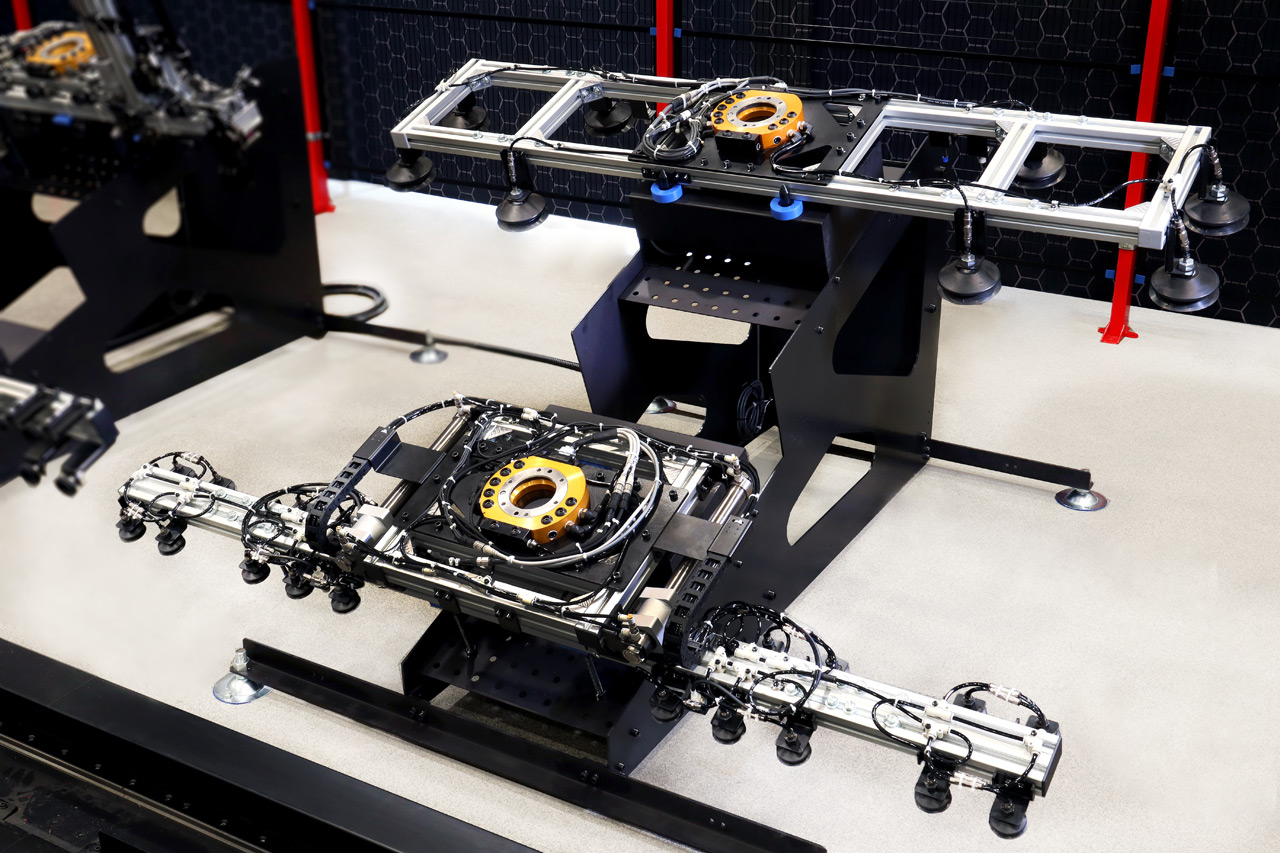

RE-GRIPPING SYSTEM:

The HG-Rm is equipped with automatic systems that enable parts to be re-gripped during the bending process. Two devices, one for panels, the other specifically for profiles, can automatically vary the support area during the bending cycle, due to powered support arms.

MAXIMUM PRECISION AND REPEATABILITY:

The HG-Rm features a number of devices and provides high precision and repeatability. The AMADA-patented gauging function ensures quick, precise positioning of the part on the back gauges, for absolute precision over the bend length. The Bi-S device is used to measure and correct the angle in real time for a precise and constant result.

DEDICATED GRIPPERS:

The HG-Rm offers a wide range of grippers, designed to handle specific parts for the maximum performance in terms of the cycle times. In particular, the sliding technology can optimise the handling cycle, with a considerable increase in productivity.

| HG-1303Rm | |

|---|---|

| Press brake: | |

| Press capacity (kN) | 1300 |

| Drive | Servo-Hydraulic press brake |

| Press beam length (mm) | 3110 |

| Stroke (mm) | 250 |

| Open height (mm) | 520 |

| Angle sensor | - |

Robot: | |

| Robot type | 6 -axes robot |

| Travel axis stroke length (mm) | 8, 4.8 in option |

| Robot payload incl. gripper (kg) | 80 |

| Manufacturer | YASKAWA |

Gripper: | |

| Gripper types: | Vacuum type, Sliding types, Combination type |

Loading: | |

| Number of loading positions | 1 |

| Vertical loading | No |

| Workpiece stack height (mm) | 300 |

Unloading: | |

| Number of unloading positions | 2 |

| Unloading method | Pallet |

Workpiece: | |

| Maximum Workpiece Size (mm) | 1250 x 2500 |

| Minimum Workpiece Size (mm) | 100 x 500 |

| Workpiece thickness (mm) | 0.5 - 6.0 |

Technical data can vary depending on configuration / options

Please contact us for more details and options or download our brochure

For your safe use.

Be sure to read the user manual carefully before use.

When using this product, appropriate personal protection equipment must be used.