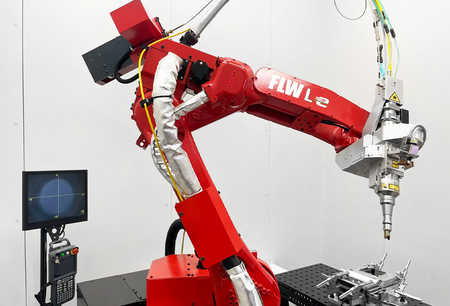

The FLW-3000 Le is a fiber laser welding machine designed to bring innovation and precision to production processes. This compact machine is the ideal solution for those seeking efficiency and quality in confined spaces, thanks to a design that combines a small footprint with high performance.

With dimensions of only 3,600 x 3,600 mm, it fits perfectly even in the most critical production environments, optimizing space and enhancing productivity.

FEATURES AND BENEFITS OF FLW-3000 Le

The FLW-3000 Le stands out for its ability to handle complex welds with exceptional precision, thanks to the patented Beam Weaving technology. This system allows the laser beam to oscillate within the torch, enlarging the weld pool without needing to move the robot. This reduces wear on mechanical components, ensuring high-quality welds, even on parts with gaps to fill.

To further enhance precision and optimize processing times, the Teaching Assist System (TAS) integrates a coaxial camera that monitors the piece's position in real time. This feature allows for the correction of misalignments directly from the touchscreen, simplifying setup and improving operational efficiency.

Finally, the compact design of the FLW-3000 Le makes it perfect for production environments with limited space. With a welding cell of only 3,600 x 3,600 mm and a robot with a 25 kg payload, it offers high maneuverability. Its compact welding head allows for work in tight spaces, such as inside boxes (300 x 300 mm), ensuring excellent performance even in the most challenging applications.

PERFORMANCE AND VERSATILITY

The compact footprint of the FLW-3000 Le makes it an extremely versatile solution, ideal for both manufacturers with their own production lines and companies involved in subcontracting. The robotic welding cell integrates easily into production layouts, ensuring automation, process stability, and high-quality, consistent welds. For subcontractors, reduced setup and programming times represent an economic advantage, making the machine efficient even for small production batches.

The FLW-3000 Le combines this flexibility with a power of 3,000 watts (3 kW), capable of handling materials such as steel and aluminum, ensuring mechanical strength and high performance even in the most complex applications. The possibility of using filler material adds further precision, allowing for welds on larger gaps and achieving impeccable results.

AN INTELLIGENT AND CUSTOMIZED SYSTEM FOR ROBOTIC WELDING

The FLW-3000 Le combines power and intelligence to offer an advanced and flexible solution. Thanks to AMNC 4ie, the numerical control (NC) system developed by AMADA, setup operations become quick and intuitive, significantly reducing tooling times and improving overall production efficiency.

To meet diverse production needs, AMADA offers a range of layout solutions designed to ensure maximum flexibility and optimize operational efficiency. But we don’t stop there: at the Welding Technical Center (WTC), we work directly with our customers to test and customize every configuration. This approach allows us to analyze processes, find innovative solutions, and develop tailored applications, creating real value for every welding project