AMADA is the technology leader in robotic fibre laser welding cells, with the new FLW-Le compact system bringing many highend features to the mid-range price point. Additional benefits of this new model are its small footprint and ability to weld inside smaller parts. The FLW-Le provides high quality welding and features beam weaving functionality as standard.

Z AXIS INDICATOR:

Using a CCD camera, the Z axis can be accurately adjusted by the operator before the first part is processed, leading to a reduction in set up parts.

COMPACT FOOTPRINT:

Due to the design of the overall welding cell, the FLW-Le can be located in many smaller factories without greatly impacting on the overall production flow.

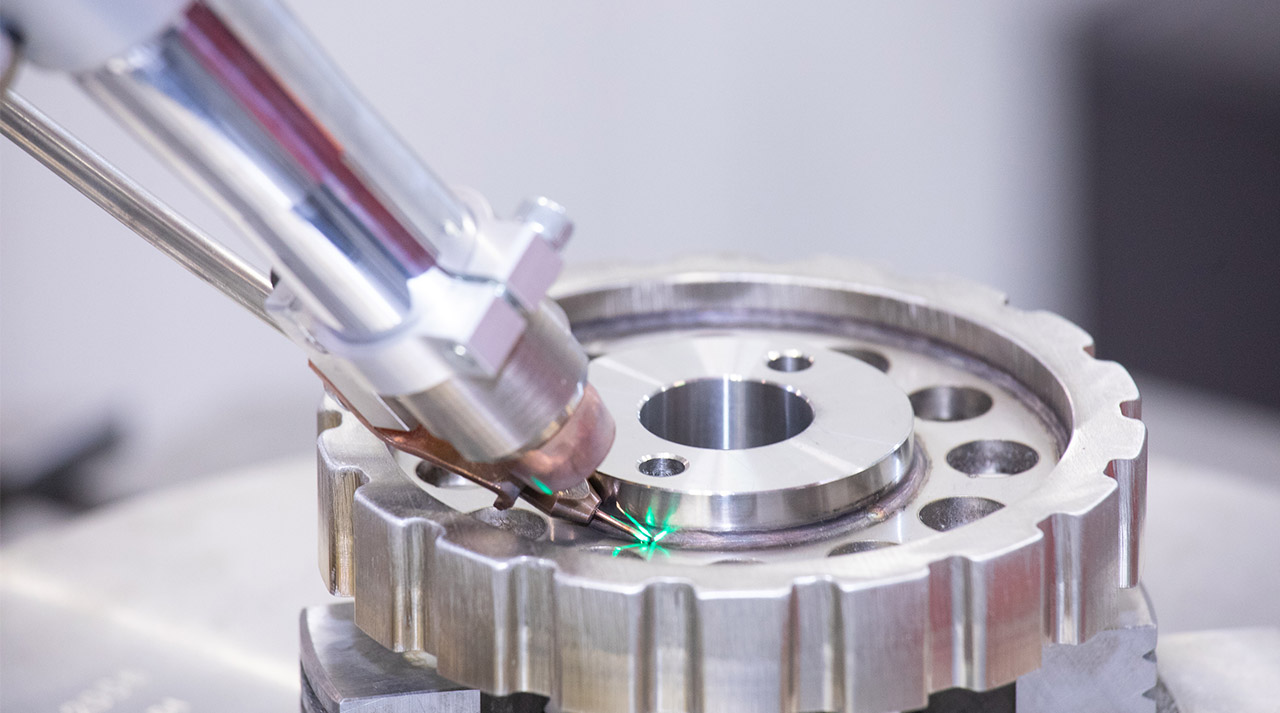

WELDING WIRE FEED:

For certain tasks, the supply of welding wire can be used, helping to bridge larger gaps, which cannot be covered even by the beam weaving process.

| FLW-3000Le | |

|---|---|

| Machine type | Fibre laser |

| Processing head | AMADA |

| NC Contoller | AMNC 4ie |

| Cabin | Full cover cabin |

Robot Specifications: | GP25 (YASKAWA) |

| Type | 6-axis articulated robot |

| Controller | YRC1000 (YASKAWA) |

Oscillator Specifications: | FL3000 |

| Rate Laser power (W) | 3000 |

| Dimensions W x H x L (mm) | 550 x 1065 x 1490 |

| Wavelength (μm) | 1.07 |

| Mass (kg) | 346 |

Dimensions: | |

| Length (mm) | 6800 |

| Width (mm) | 5500 |

| Height (mm) | 2050 |

Technical data can vary depending on configuration / options

Please contact us for more details and options or download our brochure

For your safe use.

Be sure to read the user manual carefully before use.

When using this product, appropriate personal protection equipment must be used.

Laser class 1 when operated in accordance to EN 60825-1