AMADA is the technology leader in fibre laser welding cells. The FLW-ENSISe welding cell has many features that make it unique in terms of welding quality, welding speed and productivity. The basic configuration of the cell consists of AMADA’s own fibre laser engine, a 6-axis robot on a linear carriageway, a turn and tilt table and an active safety cabin. Depending on the expansion level, additional, useful features can be added.

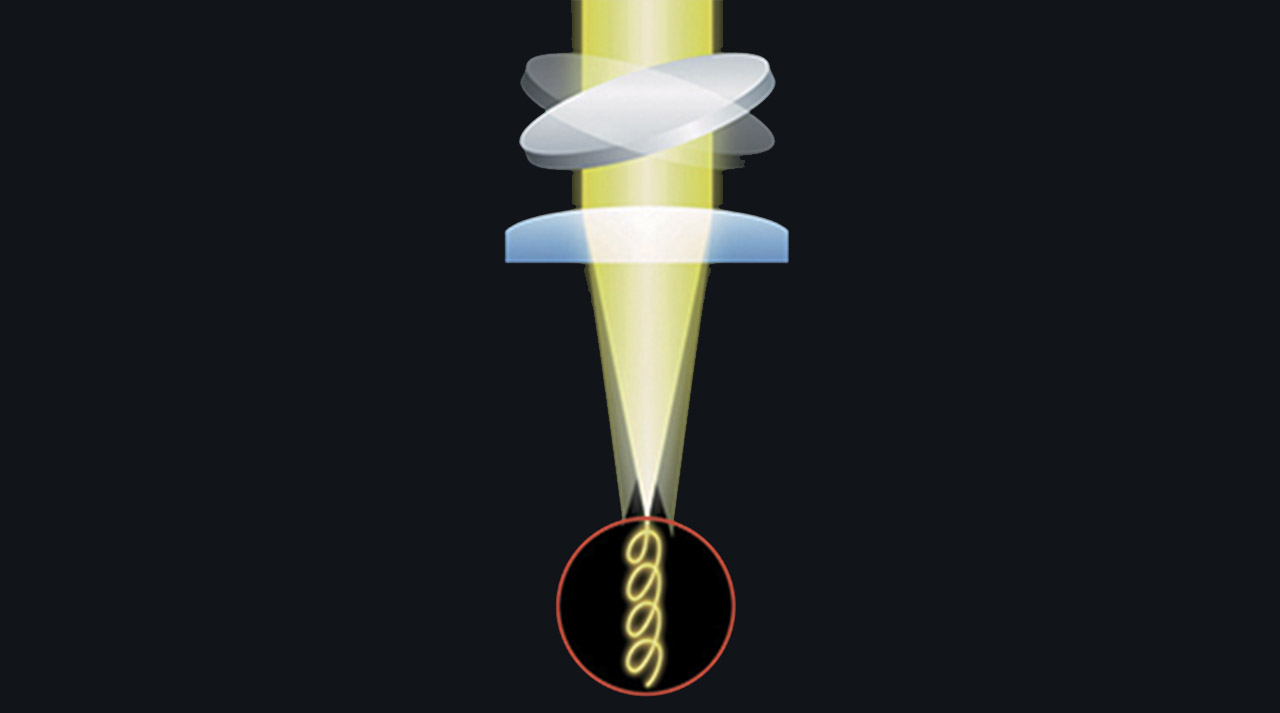

BEAM WEAVING:

This unique system rotates the actual laser beam using a weaving lens, rather than relying on a rotational motion of the robot, to allow much wider gaps to be cleanly welded. This results in much smoother, consistent welds and a higher quality part.

CHOICE OF POWERS:

The FLW-ENSISe solution can be supplied with 3kW or 6kW of welding power to provide the most suitable level of welding capability for your production

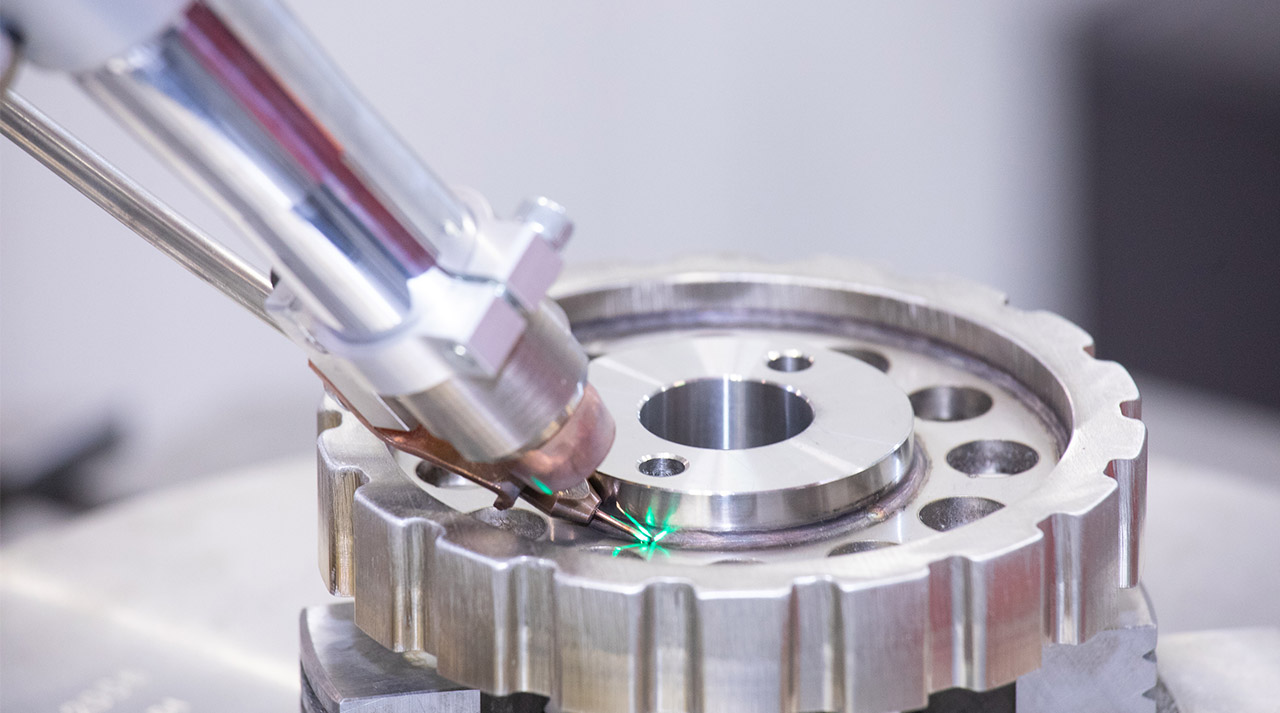

WELDING WIRE FEED:

For certain tasks, the supply of welding wire can be activated at any time. This can be varied even within a part and also helps to bridge larger gaps, which cannot be covered even by the beam weaving process.

| FLW-3000ENSISe M3 | FLW-3000ENSISe M5 | |

|---|---|---|

| Laser power (W) | 3000 | 3000 |

| Machine type | Fibre laser | Fibre laser |

| Processing head | AMADA | AMADA |

| Carriage travel stroke (mm) | 3000 | 4000 |

| Max. carriage travel speed (m/min) | 60 | 60 |

| Carriage repeatable positioning accuracy (mm) | ± 0.1 | ± 0.1 |

| Positioner table payload capacity maximum (kg) | 500 | 500 |

| Positioner table rotating axis | ± 720 ° | ± 200 ° |

| Positioner table tilting axis | ± 90 ° | ± 90 ° |

Robot Specifications: | ||

| Type | Vertical articulated 6-axis robot | |

| Controller | YRC1000 | YRC1000 |

Dimensions*: | ||

| Length (mm) | 7500 | 8500 |

| Width (mm) | 5000 | 4500 |

| Height (mm) | 3700 | 3700 |

| Weight (kg) | 13850 | 15265 |

*Dependent on work type and customer requirements.

Technical data can vary depending on configuration / options

Please contact us for more details and options or download our brochure

For your safe use.

Be sure to read the user manual carefully before use.

When using this product, appropriate personal protection equipment must be used.

Laser class 1 when operated in accordance to EN 60825-1