AS-III

More

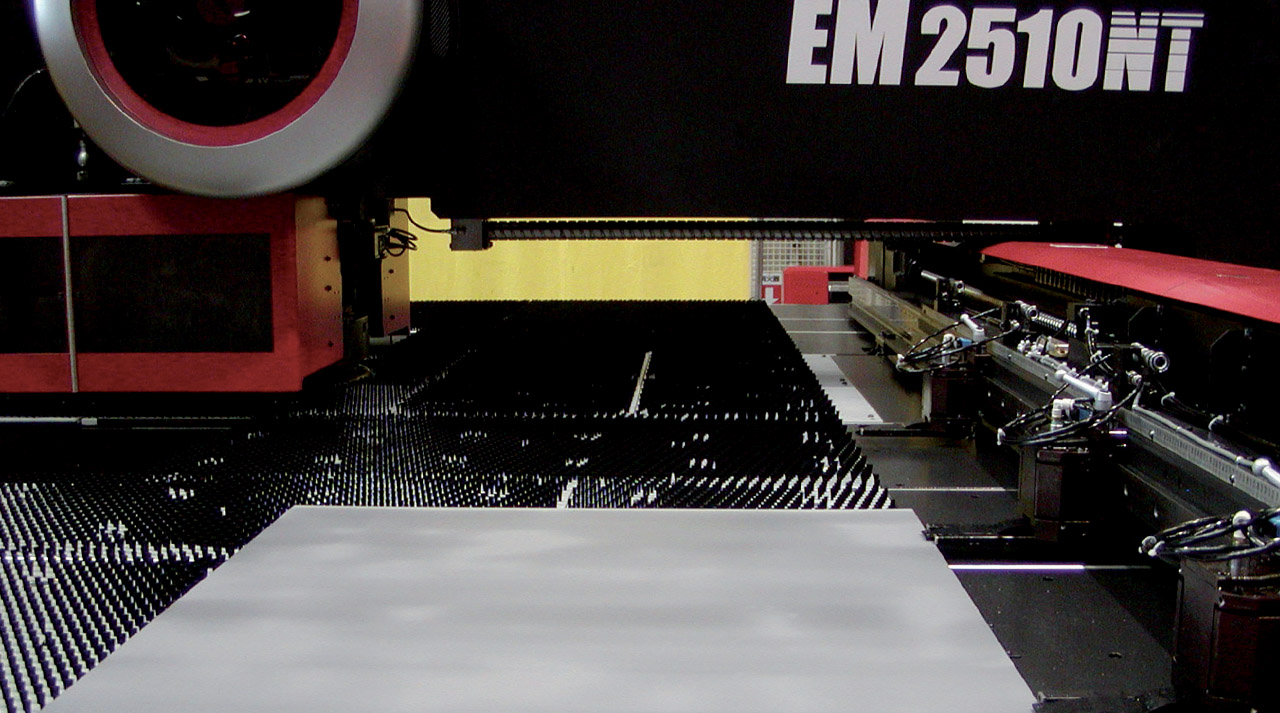

The EM-MII range features an unrivalled 30 ton dual servo electric motor punching system and AMADA’s industry leading tool turret which is available in two different configurations (Z and K versions). These features provide quicker, superior quality processing.

The optional tool identification systems and dedicated tapping units reduce setup times and allow for even more process integration for higher efficiency.

QUICK SETUP:

The high capacity turret reduces machine tooling requirements. The Z type turret has been designed for the quick replacement of punches and dies.

ID TOOLING:

AMADA ID Tooling System (AITS) prevents errors during tool set up, and helps monitor and optimise tool life, so the quality of processed parts is not affected.

EXTENDED WORK AREA:

The machine structure (in 3612 versions) enables sheet metal measuring 3050 x 1525 mm to be processed, without the need for repositioning.

| EMZ-3510MII (45) | EMK-3510MII (58) | |

|---|---|---|

| Press capacity (kN) | 300 | 300 |

| Positioning accuracy (mm) | ± 0.1 | ± 0.1 |

| Number of stations | 45 | 58 |

| Machine frame | Bridge frame | Bridge frame |

| Axis travel distance (mm) | 2500 x 1270 | 2500 x 1270 |

| Machine table type | Brush table | Brush table |

Dimensions: | ||

| Length (mm) | 4998 | 4998 |

| Width (mm) | 5128 | 5128 |

| Height (mm) | 2342 | 2342 |

| Weight (kg) | 19000 | 19500 |

| EMZ-3612MII (45) | EMK-3612MII (58) | |

|---|---|---|

| Press capacity (kN) | 300 | 300 |

| Positioning accuracy (mm) | ± 0.1 | ± 0.1 |

| Number of stations | 45 | 58 |

| Machine frame | Bridge frame | Bridge frame |

| Axis travel distance (mm) | 3050 x 1525 | 3050 x 1525 |

| Machine table type | Brush table | Brush table |

Dimensions: | ||

| Length (mm) | 5436 | 5436 |

| Width (mm) | 6212 | 6212 |

| Height (mm) | 2342 | 2342 |

| Weight (kg) | 21000 | 21500 |

Technical data can vary depending on configuration / options

Please contact us for more details and options or download our brochure

For your safe use.

Be sure to read the user manual carefully before use.

When using this product, appropriate personal protection equipment must be used.